An exploration of the exciting field of 3D Printing and 3D Printers in the fab shop, at work, at home and in school.

Tuesday, 8 September 2009

3D Printing a World of Design

http://futurismic.com/2009/08/26/3d-printing-a-world-of-design/

"It’s 2017. I go in to the hairdresser to get dolled up for a night out. I bring a sample of the pale blue color of the dress I’m going to print for tonight and one of the taupe shoes I’ve already made this morning. The hairdresser uses a hand-held machine to scan my samples and my scalp, and then she sends a patented design for a hair band only available through her salon to the 3D printer in the back. Twenty minutes later, just as she’s finishing with her blow dryer, one of her assistants brings the hair band, which fits and looks perfect. After my night out, the hair band, shoes, and dress all go into the recycler to be sorted into raw material for my wardrobe the next night out.

It’s 2019 ..."

Saturday, 15 August 2009

Saturday, 8 August 2009

Friday, 7 August 2009

3D Printing in Metal! Surely that is not possible?

3D printing can create functional metal parts printed directly from CAD.

[snip] The ProMetal three dimensional printing process is an accurate, flexible, and reliable tool that can create extremely intricate metal tools, workpieces and molds. In many cases, ProMetal is capable of producing components that would be impossible to produce by any other means.

ExOne holds patents on 3D Printing in Metal

[snip] As I write this, I'm making things mostly by direct-metal printing: there's a machine that takes a CAD file specifying a 3D object, and builds the object, physically, as metal. If this sounds like science fiction to you, well it might.

I don't (yet) have this machine on my desk, I just rent time on it. The process that I use is proprietary to Ex One, and they do the printing. What follows is very much a layman's explanation of how it works -- for more technical information, please visit Ex One's Prometal site. (Some information about other types of 3D printing is here.)

To start with, the design is laid down, one layer at a time, in stainless-steel powder held in place by a laser-activated binder. You can see the layering on the finished pieces, it is the source of the characteristic texture of my work. Each layer is .004" to .007" thick.

The steel granules are so fine that they feel like very heavy, cool flour. During the build the extra unbound powder supports the piece, so no extra structure is needed to handle undercuts. The powder is very flowable, it's not caky like cornstarch, so removing this extra supporting powder from the finished model is quite easy. It slides off with a little shake and a light brush, and it can be poured out of interior spaces.

After the whole model is built up, and the extra powder is shaken off, the piece goes into an oven, where heat drives off the binder and fuses the steel powder. There's just enough heat to make the granules weld together where they touch, without collapsing the entire piece into a puddle. This produces a porous steel part that's about 60% dense, like the one at left.

This "green" material is matte gray, feels like sandstone, and won't take a polish. It is soft enough to cut quickly with a hacksaw, but can't quite be dented with a fingernail. It's considerably lighter than steel, which is not surprising since it's 40% air.

An artist exploring math and science in sculpture using 3D Printing in a variety of media

Thursday, 23 July 2009

Objet shows Printed Objects

Amazing 3D 'printed' objects from ObJet ... but Objet are really going to have to work on improved communications in the first part of this video. I failed to count how many times the presenter explained what was going on while managing to explain nothing at all!

Wednesday, 22 July 2009

Thursday, 16 July 2009

Objects are print-outs!

[snip] ... the "objects are print-outs" line stuck with me. It encapsulates not just an attitude towards material possessions, but--in one pithy phrase--one possible shape of the next economy. Take a design for a simple product--an engine part, for example, or a piece of silverware, and feed it into a computer. Press "print." Out pops (for a sufficiently wide definition of "pops") a physical duplicate, made out of materials plastic, ceramic, metal -- even sugar. Press "print" again, and out comes another copy--or feed in a new design, for the next necessary object.

http://www.fastcompany.com/blog/jamais-cascio/open-future/material-issue

Tuesday, 14 July 2009

3D Printing - The Next File Sharing?

[snip] the future will see file-sharing networks trade designs for (possibly copyrighted) products. Make a bedside lamp, flyswatter, pair of sandals, plastic wine glass or a coat hook, rather than buying one. The makers say that the next version will even be able to make its own electronic circuitry.

Pirate Bay founder labels 3D printers "the future of sharing"

Friday, 10 July 2009

Fab @ Home Video

Now you can buy relatively cheap 'kits' for 3D printing. The printing process is simpler than the high end printers from ZCorp or Objet, results won't be as professional, but the fact this is possible, at this price point, is testament to the inherent simplicity of the 3D printing process and the rapid comoditization of the parts required to build a 3D printer. Watch this video, think about your application and then go buy yourself a kit and start to Fab @ Home:

Saturday, 27 June 2009

Models of everything!

There will soon be models of everything, everywhere. [snip] It's a defining moment in a parent's life: Seeing their unborn child's image on an ultrasound for the first time. Now pregnant women could have the chance to hold a life-size model of their unborn baby.

Stunning new technology allows parents to hold a life-size model of their unborn child

Stunning new technology allows parents to hold a life-size model of their unborn child

Stunning new technology allows parents to hold a life-size model of their unborn child

Stunning new technology allows parents to hold a life-size model of their unborn child

Monday, 15 June 2009

"One Round Left" by Jessie Sasser, PictureBandit.com

Jessie Saaser explains the process of creating a 3D sculpture:

PictureBandit.com

Thursday, 11 June 2009

Consumer services are going to explode ...

Shapeways does it again .... 3D printed light sculptures (3D photographs). Watch and love. I need one. I do. I really do.

Inside thinglab.co.uk - skulls, color, face scans and more ...

Must visit these guys. One of the best videos I have seen showing the range of possibilities for 3D printing:

Fused deposition modeling

Which 3D printing technology will 'win' in the market, or are different approaches going to find specific uses. Here's one way: fused deposition modeling. Durable, accurate, parts ... from your desktop. Slice the STL files and generate 3D support structure and extrusion paths. Solid material (thermoplastic) in filament form is heated to a less viscous state for extrusion. The model is built layer by layer, from the bottom up. Soluble supports are simply dissolved in a water based solution resulting in a part with smooth surface finish and fine detail in tact.

Inkjet Gurus from HP Scitex = Objet Geometries

Squirting solid stuff (photopolymer cured instantly) is inkjet science stuff. The part is fully ready to be used at end of 3D print. Explains the background to this technology, and describes some of the materials used. 16micron layer allows very small surface on bio-compatible materials. How to produce moving parts .... squirt those air pixels.

Solid color model copying and printing

As this field develops, new terminology will emerge. It's important the concept is 'understood', is an instant. I was struck by the terms used in this excellent video:

From a 3D computer file emailed from Australia, to a model in your hand!

Wednesday, 10 June 2009

Materials innovations for 3D Printing

My guess is, there will be considerable innovation in materials for 3D printing over the next decade. Here is a snip from ZCorp:

[snip] Z Corporation today released zp(R)150, a premium composite build material for its ZPrinter(R) 450 and ZPrinter(R) 650 3D printers. zp150 improves the strength and color of 3D printed models for 3D CAD while producing whiter whites for applications such as architectural modeling where true white is the traditional standard.

Z Corporation Introduces zp150 Composite Material for Tougher 3D Printed Parts, Rich Colors and Whiter Whites

Jay Leno - 3D Print Old Car Parts - Video and Article

Jay Leno - US TV Host - has a lot of old cars with a lot of obsolete parts. When he needs to replace these parts, he skips the error-prone machinist and goes to his rapid prototyping 3D printer. Simply scan, print and repeat. Read the article, and watch the video. As he says 'Pretty amazing"

Jay Leno’s 3D Printer Replaces Rusty Old Parts

Tuesday, 9 June 2009

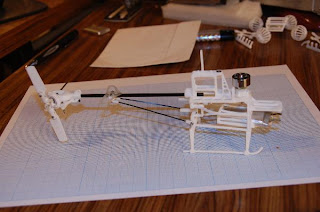

Now I'm convinced - print your own 3D Helicopter

3D Printing is going to be big. Why? Take a look at this:

Printing a 3D Model Helicopter

And it flies!

3D Printing is going to be big. Why? Take a look at this:

Printing a 3D Model Helicopter

And it flies!

Tuesday, 2 June 2009

Is it really this easy? A nice video from Dimension

Everything you ever wanted to know about Dimension 3D Printers:

Tuesday, 26 May 2009

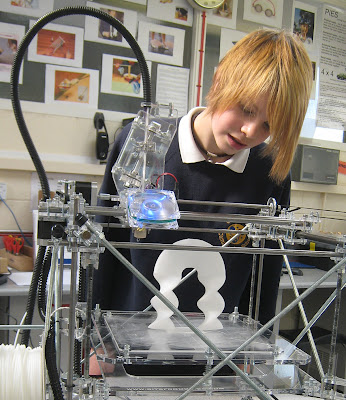

With more 3D printer 'kits' appearing, schools are also starting to print in 3D

Schools and Colleges are already starting to teach Rapid Prototyping, but the technology is too costly to be accessible to everyone.. until now! For well under £1,000, you can create 3D shapes in a number of different materials.

The RapMan not only enables the teaching of RP and RM, but also is supplied in kit form, so building the RapMan contributes towards the teaching and learning of engineering.

Rap-Man

Schools and Colleges are already starting to teach Rapid Prototyping, but the technology is too costly to be accessible to everyone.. until now! For well under £1,000, you can create 3D shapes in a number of different materials.

The RapMan not only enables the teaching of RP and RM, but also is supplied in kit form, so building the RapMan contributes towards the teaching and learning of engineering.

Rap-Man

Thursday, 21 May 2009

3D Print in Sugar? Yum!

Now things are getting a bit crazy. The CandyFab project is using 3D printing techniques, to print with Sugar. Yes .. the edible crystalline substance, mainly sucrose, lactose, and fructose. It's testament to the simplicity of 3D printing that this is possible.

CandyFab Project

[snip] The goals of The CandyFab Project are to reduce the costs associated with three-dimensional solid freeform fabrication, and to promote the use of fabrication technologies for culinary, educational, and artistic purposes.

Now things are getting a bit crazy. The CandyFab project is using 3D printing techniques, to print with Sugar. Yes .. the edible crystalline substance, mainly sucrose, lactose, and fructose. It's testament to the simplicity of 3D printing that this is possible.

CandyFab Project

[snip] The goals of The CandyFab Project are to reduce the costs associated with three-dimensional solid freeform fabrication, and to promote the use of fabrication technologies for culinary, educational, and artistic purposes.

Thursday, 14 May 2009

3D Printing from Holograms

A company is bringing full-color, glasses-free holograms to life, and R2D2’s got nothing to do with it. Instead, Zebra Imaging creates true 3D objects through software and a fast, powerful printing machine.

[snip] ZI’s software places a virtual camera inside every point of a digital model’s holographic vertical plane, in order to record its surface volume. Zebra then prints the data (containing distinct POVs) to a plastic polymer, creating a sheet full of 1-mm holo tile encryptions. Each tile is basically an image data conductor sensitive to light. When light is shined, its energy scatters around and all image angles are revealed at once, popping up a free-standing 3D model. When you reach out to “touch” the 3D buildings in a demo, you feel nothing but air, revealing a true optical illusion.

This tech is important for a few reasons. The wide angles and true depth volume of the renders help people collaborate easier in real space, as opposed to a 2D screen (and might help avoid visual fatigue). And the 3D slabs are cheaper and faster to make than models made of other materials, like clay. This is why the U.S. Army likes them — maps of constantly changing battlefields can be printed on the fly.

From Three companies to watch in 3D

A company is bringing full-color, glasses-free holograms to life, and R2D2’s got nothing to do with it. Instead, Zebra Imaging creates true 3D objects through software and a fast, powerful printing machine.

[snip] ZI’s software places a virtual camera inside every point of a digital model’s holographic vertical plane, in order to record its surface volume. Zebra then prints the data (containing distinct POVs) to a plastic polymer, creating a sheet full of 1-mm holo tile encryptions. Each tile is basically an image data conductor sensitive to light. When light is shined, its energy scatters around and all image angles are revealed at once, popping up a free-standing 3D model. When you reach out to “touch” the 3D buildings in a demo, you feel nothing but air, revealing a true optical illusion.

This tech is important for a few reasons. The wide angles and true depth volume of the renders help people collaborate easier in real space, as opposed to a 2D screen (and might help avoid visual fatigue). And the 3D slabs are cheaper and faster to make than models made of other materials, like clay. This is why the U.S. Army likes them — maps of constantly changing battlefields can be printed on the fly.

From Three companies to watch in 3D

Alphabet Blocks

Sometimes it's the little things that lead one to realize that 3D Printing is going to be wildly popular. Jordan Berger, New Paltz High School, New York, is a finalist in Dimension Printing's Extreme Redesign Contest competition.

[snip] This new redesigned alphabet block would also be more educational then the traditional block. Usually with blocks, the only language is English, children growing up with the new blocks may become global marketers, dealing in many different languages since the new block increases exposure to different languages. Also, the child's creativity is increased by seeing the drawing symbolizing the letter, formulating the link and eventually spelling. These blocks may aide the child in their education in the future, and as a result, be an integral part of their life.

Sometimes it's the little things that lead one to realize that 3D Printing is going to be wildly popular. Jordan Berger, New Paltz High School, New York, is a finalist in Dimension Printing's Extreme Redesign Contest competition.

[snip] This new redesigned alphabet block would also be more educational then the traditional block. Usually with blocks, the only language is English, children growing up with the new blocks may become global marketers, dealing in many different languages since the new block increases exposure to different languages. Also, the child's creativity is increased by seeing the drawing symbolizing the letter, formulating the link and eventually spelling. These blocks may aide the child in their education in the future, and as a result, be an integral part of their life.

Tuesday, 5 May 2009

From Digital Life to Real Objects!

ProTocuBe uses the potential of 3D technology to make ideas real and to visualize projects. In particular, ProTocuBe uses various Rapid Prototyping technologies to make physical models, real-scale prototypes and scale models, for architecture, design and many different fields of application.

Rapid Prototyping is a series of systems able to create an object automatically, starting from a digital 3D model, in short times, without limits referring to the geometrical complexity, with a deep detail, in various materials, also coloured and textured.

Here is a video of a series of workshops led by ProTocuBe as they worked with students of 3D technologies.

Thursday, 23 April 2009

3D Printed Art

It used to be impressive when an artist created complex geometric shapes and made them into real objects. Even if you didn't like the shape, you had to admit it was a feat. But these days, with a software program and 3D printing, it is possible to produce the seemingly impossible 3D 'art' in a snap. Does this mean 3D Printing lessons ART? In some cases, yes. It will be much harder to spot the 'real' thing. Stuff like this snail shell-esque math art will become commonplace. Today's 3D software makes things too easy. Zbrush is an example. So is there the possibility for true art in 3D Printing? Of course. But how will you recognize it?

3D Printed Snail Shell-Esque Math Art

It used to be impressive when an artist created complex geometric shapes and made them into real objects. Even if you didn't like the shape, you had to admit it was a feat. But these days, with a software program and 3D printing, it is possible to produce the seemingly impossible 3D 'art' in a snap. Does this mean 3D Printing lessons ART? In some cases, yes. It will be much harder to spot the 'real' thing. Stuff like this snail shell-esque math art will become commonplace. Today's 3D software makes things too easy. Zbrush is an example. So is there the possibility for true art in 3D Printing? Of course. But how will you recognize it?

3D Printed Snail Shell-Esque Math Art

Wednesday, 22 April 2009

Design, Make, Collect - It's easy at Shapeways

If you ever wondered "Should I - should I go ahead of try out one of those 3D Print services, but were worried it might get complex, take a look at this compelling video from Shapeways. It shows the simplicity of the end-to-end online process of designing, ordering, printing and .... Ta Da ... delivery in 3D. Some call it Make On Demand.

Shapeways

Saturday, 18 April 2009

Moddler

[snip] Moddler is the premier 3d printing company for today's digital entertainment creators, including digital film studios, visual effects companies, video game companies, and individual artists. We specialize in turning your digital models into incredibly detailed physical models to be used as maquettes for design validation, high-end swag for clients or team members, or physical props. These models are printed through a digital process, just like inkjet printing, that results in the creation of very fine detail with a high degree of accuracy.

Nice view of the studio.

[snip] Moddler is the premier 3d printing company for today's digital entertainment creators, including digital film studios, visual effects companies, video game companies, and individual artists. We specialize in turning your digital models into incredibly detailed physical models to be used as maquettes for design validation, high-end swag for clients or team members, or physical props. These models are printed through a digital process, just like inkjet printing, that results in the creation of very fine detail with a high degree of accuracy.

Nice view of the studio.

Thursday, 16 April 2009

Color 3D Print Demo - ZPrinter 450

A neat video of a 3D Printer in an office location printing in color.

Ponoko

What will 3D Printing mean for a Make On-Demand service like Ponoko?

[snip] We wanted to create a place where you could shop for and make things that are completely original, and do this in the greenest way possible. So we made Ponoko ... the first online shop for individualized goods – things designed and made just for you.

Ponoko

Wednesday, 1 April 2009

MakerBot

3D Printing is in some ways a rather simple technology. Components of a 3D Printer will rapidly become a commodity. And this is why 3D Printing might be big! Witness the RepRap community, Fab@Home and MakerBot Industries.

MakerBot create open source robot kits that transform your digital designs into physical objects automatically. The kits are modular, modifiable, and built to be hacked. [quote] "We can't wait to see what you do with them."

MakerBot Industries

MakerBot Videos

3D Printing is in some ways a rather simple technology. Components of a 3D Printer will rapidly become a commodity. And this is why 3D Printing might be big! Witness the RepRap community, Fab@Home and MakerBot Industries.

MakerBot create open source robot kits that transform your digital designs into physical objects automatically. The kits are modular, modifiable, and built to be hacked. [quote] "We can't wait to see what you do with them."

MakerBot Industries

MakerBot Videos

Sunday, 29 March 2009

Friday, 27 March 2009

ObJet Printing

[snip] Parts that are difficult or impossible to make by conventional subtractive methods can be produced by additive fabrication but there are still a few limitations to what can be printed and these include wall thickness, overall physical size and the ability of the software to process your digital designs.

3D Printing You!

[snip] Just last week I wrote about advances in medical technology that were making print-out flesh and organs possible. Now they're printing out bones. The tests at Insel hospital, Switzerland, were so successful that an exact printout replica of a human thumb bone has been created for the first time ever.

3D Printers to Make Replacement Bones

[snip] Just last week I wrote about advances in medical technology that were making print-out flesh and organs possible. Now they're printing out bones. The tests at Insel hospital, Switzerland, were so successful that an exact printout replica of a human thumb bone has been created for the first time ever.

3D Printers to Make Replacement Bones

Just how important is 3D Printing?

Replicator and Fabbaloo exchange views.

Why 3D Printers won't go mainstream

or

Five Reasons Why [they will]

What's your opinion?

Replicator and Fabbaloo exchange views.

Why 3D Printers won't go mainstream

or

Five Reasons Why [they will]

What's your opinion?

Thursday, 26 March 2009

Materialize Magics Software

[snip] For everyone who works with STL files, Magics is the ideal and complete software solution. Magics sets the standard for ease of use and efficiency when working with faceted data. It offers advanced and highly automated tools for STL manipulation. You can correct an STL file in a matter of minutes with the help of unmatched tools to interact directly on defective triangles. Magics gives you full control over your STL files. Among the offered functions you find:

* Visualisation, measuring and manipulation of STL files

* Fixing STL files, uniting shells, trimming surfaces, double triangle detector

* Cutting STL files, punching holes, extruding surfaces, hollowing, applying offset

* Boolean operations, triangle reduction, smoothing, labelling

* Nesting, collision detection

* Colouring STL files

Materialize Magics

[snip] For everyone who works with STL files, Magics is the ideal and complete software solution. Magics sets the standard for ease of use and efficiency when working with faceted data. It offers advanced and highly automated tools for STL manipulation. You can correct an STL file in a matter of minutes with the help of unmatched tools to interact directly on defective triangles. Magics gives you full control over your STL files. Among the offered functions you find:

* Visualisation, measuring and manipulation of STL files

* Fixing STL files, uniting shells, trimming surfaces, double triangle detector

* Cutting STL files, punching holes, extruding surfaces, hollowing, applying offset

* Boolean operations, triangle reduction, smoothing, labelling

* Nesting, collision detection

* Colouring STL files

Materialize Magics

3D Creation Lab UK

[snip] Using a technology called 3D printing, 3D Creation Lab can turn your designs into reality. Just send us your design for a quotation and when you are ready to order we will print it out and ship it to you - simple. This service is available to anybody, we don't just supply to businesses we will supply to anybody that can benefit from the 3D printing process.

[snip] Using a technology called 3D printing, 3D Creation Lab can turn your designs into reality. Just send us your design for a quotation and when you are ready to order we will print it out and ship it to you - simple. This service is available to anybody, we don't just supply to businesses we will supply to anybody that can benefit from the 3D printing process.

Tuesday, 24 March 2009

ZCorp Spectrum Z510

[snip] The premier feature of the Z510, however, is its ability to print objects in full color—a feature that is unique among other RP technologies. Parts can be printed with textual labels, colored surfaces, or even with photobased textures. Also of note is the ability of the Z510 to build models with moving parts. Because parts are separated by loose powder, they can be built up against other parts without joining, so that, for instance, gears can be built onto axles that connect to other gears and axles and form a functioning machine.

Three Dimensional Printing At the Advanced Media Studio

[snip] The premier feature of the Z510, however, is its ability to print objects in full color—a feature that is unique among other RP technologies. Parts can be printed with textual labels, colored surfaces, or even with photobased textures. Also of note is the ability of the Z510 to build models with moving parts. Because parts are separated by loose powder, they can be built up against other parts without joining, so that, for instance, gears can be built onto axles that connect to other gears and axles and form a functioning machine.

Three Dimensional Printing At the Advanced Media Studio

Subscribe to:

Comments (Atom)